Production

Balancing speed and reliability is a big challenge. Remaining flexible and responsive in an automated environment is a challenge.

Our strategy for achieving this: consistent and targeted investment in three key areas:

The production tool

Consistent, efficient, organized around three automatic Roxane type weighing robots, optimized by means of a common supervision system

Facilities

Equipped and arranged for an efficient flow of goods including 2 thermo-regulated production units, small and large volumes, using the same manufacturing processes and the same batches of raw materials

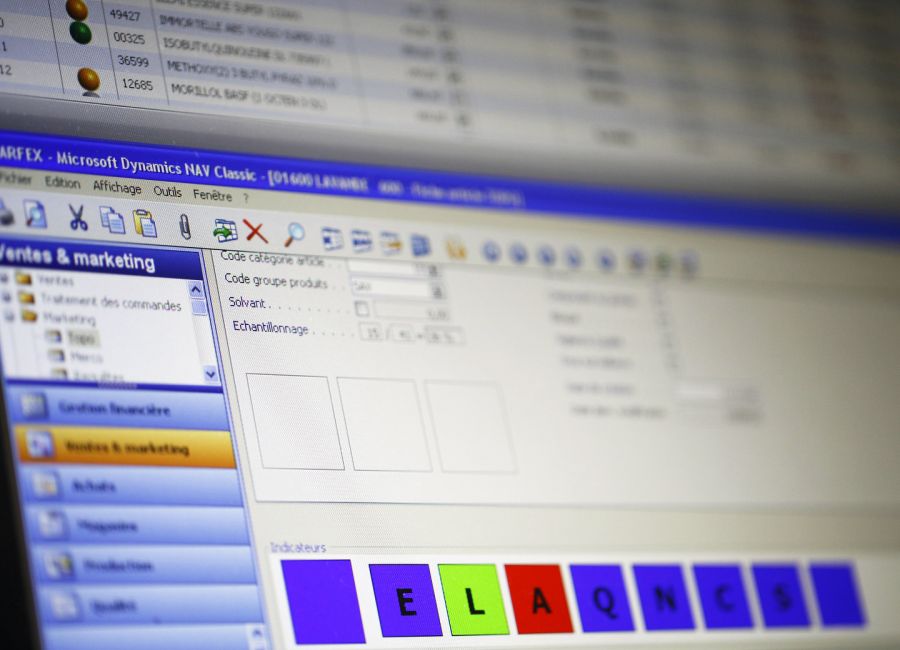

IT

ERP management of the supply-chain, manufacturing and shipping functions with full traceability.

Powerful planning tools make us highly responsive and always under the control of our systems, as well as giving us manufacturing lead times of only a few days. The use of Flashcode technology to oversee all weighings ensures the highest level of reliability and reproducibility of our compounds.

This level of performance, driven by a continuous improvement process, gives us an annual production capacity of 20,000 batches manufactured at an automated rate of 90%.

Our teams therefore work in an advantageous environment, where people and machines complement, control and supervise each other.